¶ 🔥 Case Study: Stronger, Faster 3D Prints with Dragon

With Helio Additive’s simulation and optimization tool, Dragon, we achieved:

- 💪 +65% increase in tensile strength (30.4 MPa → 50.3 MPa)

- ⚡ 39% faster print time (1h 43m → 1h 3m)

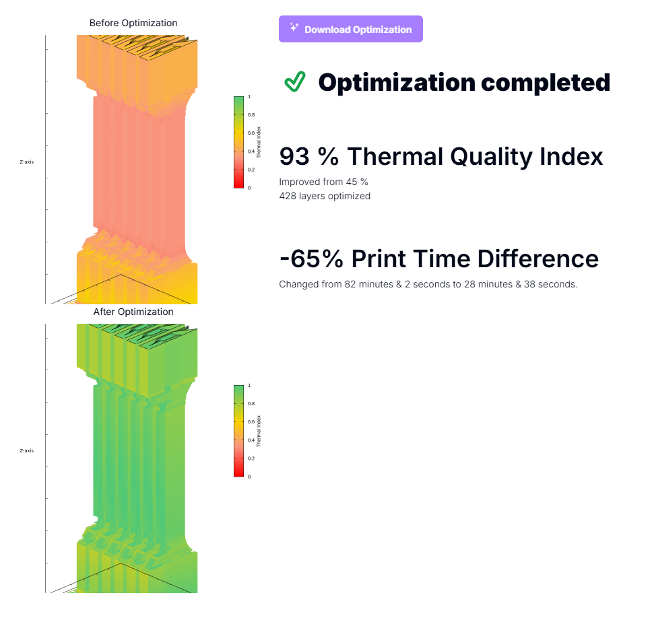

- 🌡️ Thermal Quality Index improved from 45% → 93%

- 🧠 Critical insight: cooling fan was hurting bonding — simulation revealed the issue

No material changes. No hardware changes. Just smarter G-code.

¶ 🧰 How to Do This Yourself

- Slice your model normally (e.g., in Bambu Studio).

- Run the G-code through Dragon for simulation and optimization.

- Review thermal maps and adjust fan or speed settings if needed.

- Print stronger parts, faster!

¶ 🐉 Stronger, Faster Prints with Dragon Optimization

We tested how much better your prints can get using Helio Additive’s simulation and optimization product called Dragon, compared to the default slicer settings in Bambu Studio for PC material.

This report explains what we tested, what the results mean, and why this matters — in simple terms anyone can understand.

¶ 🧪 What Did We Test?

We printed and tested standard tensile test parts using two approaches:

- Using Bambu Lab’s default PC settings

- Using Dragon-optimized G-code based on Helio Additive’s simulation and optimization engine

Then we compared:

- How strong the printed parts were (tensile strength)

- How long each print took (print time)

- How well the temperature was maintained during printing (thermal index)

¶ 🔍 What is a Tensile Test?

A tensile test checks how much pulling force a part can take before it breaks.

To do this, we used a standardized part shape called the ISO 527-2 1A tensile bar, scaled to 50% in height. These samples were pulled in a mechanical tester until they snapped, and we recorded the tensile strength in MPa (megapascals).

¶ 🧪 How We Printed the Test Parts

To make sure each of the five test samples was printed the same way:

🧵 We printed them one at a time, in sequence.

This made the printer always start each part from the same position, with the same toolpath and cooling conditions.

By doing this, we avoided any differences that might happen if the printer moved between parts (like uneven cooling or timing). It helped us make sure that any change in strength came from the G-code optimization — not from how the parts were arranged or printed.

¶ 📚 Key Terms Explained

¶ 🔗 Bonding

Bonding is how well each printed layer sticks to the next one. Poor bonding leads to weak parts. Good bonding happens when the new layer melts into the previous one while it’s still warm.

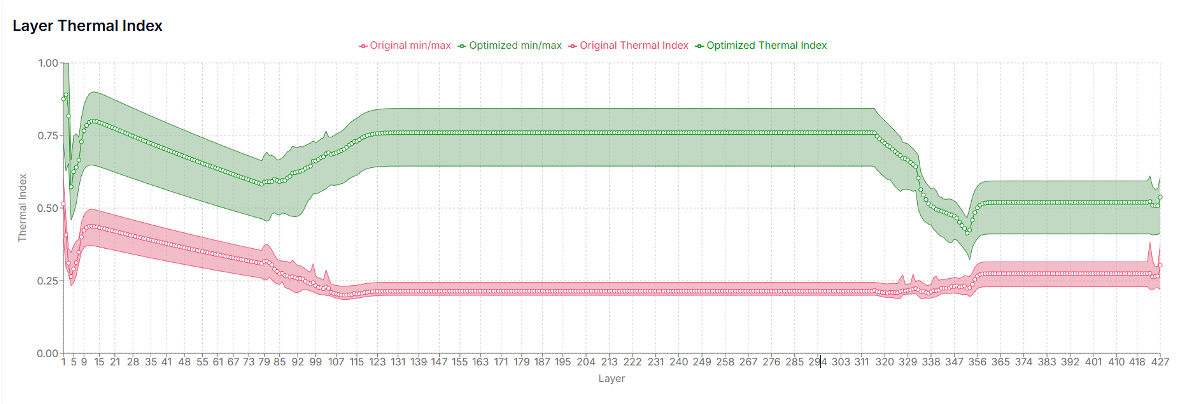

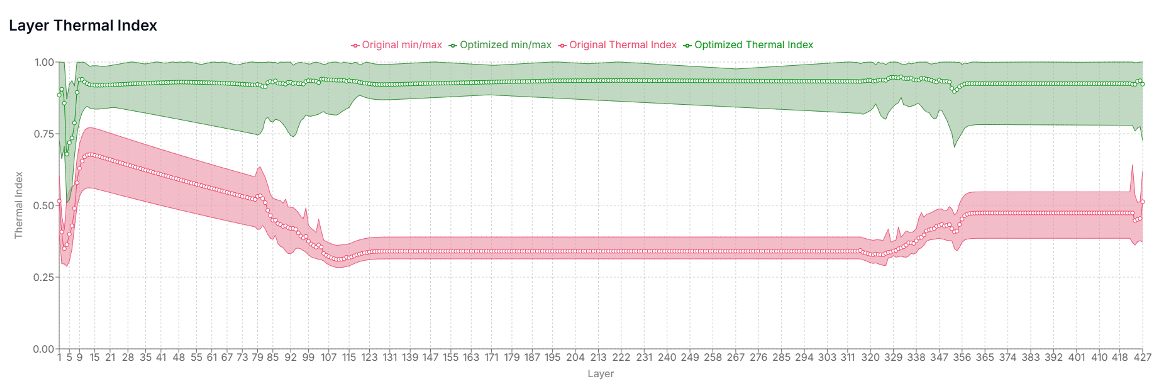

¶ 🔥 Thermal Index

This is a value that helps us understand how close the print temperature is to ideal conditions for bonding.

-

In most technical cases, the thermal index ranges from -1 to +1, where:

0= perfect bonding temperature< 0= too cold, poor bonding> 0= too hot, risk of deformation or sagging

-

For this case study, we simplified the scale from 0 to 1, where:

0= too cold1= ideal- More green = better bonding conditions

¶ 🧪 Tensile Strength (MPa)

This is how strong the part is when pulled apart. Higher MPa = stronger print.

¶ 🕓 Print Time

Total time the printer takes to finish the job. Faster is usually better — as long as it doesn't hurt quality.

¶ ⚙️ What is Dragon?

Dragon is a product by Helio Additive that simulates and optimizes your G-code before printing.

It helps you:

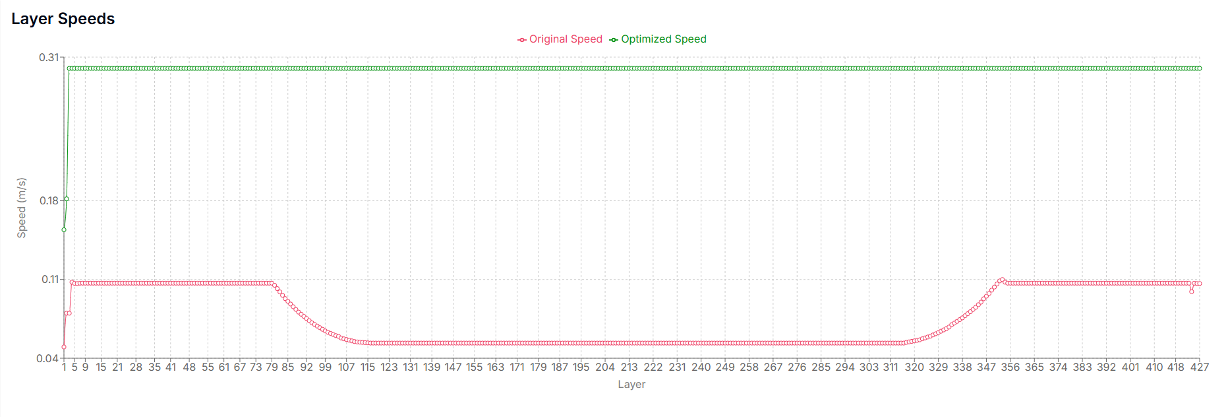

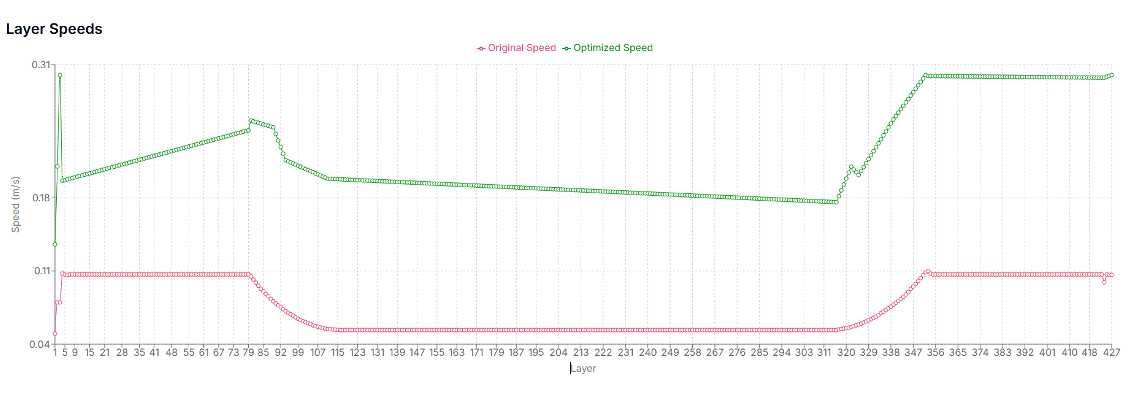

- Adjust speed layer-by-layer to improve bonding and reduce thermal stress

- Analyze how temperature affects print quality

- Find the fastest way to print without sacrificing strength

🧠 Dragon doesn’t just optimize blindly — it uses a physics-based simulation to predict how your part heats and cools in real time.

📌 Note:

Currently, Dragon focuses on speed optimization only.

Automatic fan speed optimization is coming soon — but for now, you can manually adjust fan settings based on Dragon’s simulation results.

¶ 🌀 Fan Analysis – Why It Matters

In this case, we noticed through simulation that the default cooling fan settings were hurting bonding quality, especially for polycarbonate (PC). Even at maximum speed, the part wasn't reaching an ideal thermal index.

So, we manually turned off the fan and re-ran the optimization in Dragon.

❗ Important: Dragon didn't automatically disable the fan — this decision was made after analyzing the results in Helio’s simulation.

Only with Helio’s simulation can you see this kind of detail and make data-driven improvements.

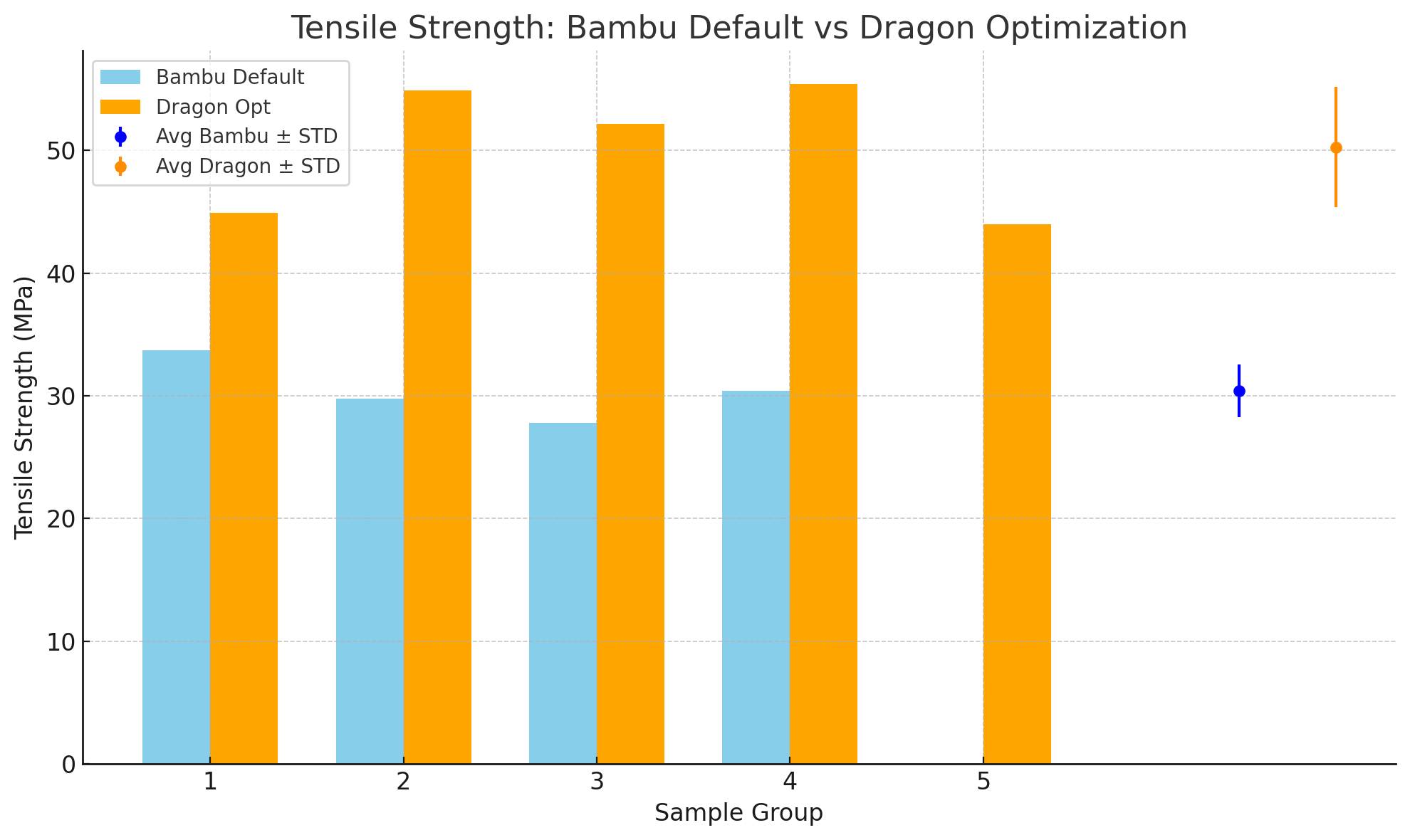

¶ ✅ Results Summary

| Metric | Default Settings | Dragon Optimization |

|---|---|---|

| Avg. Strength | 30.42 MPa | 50.28 MPa (+65%) |

| Print Time | 1h 43min | 1h 3min (-39%) |

| Thermal Quality | 45% | 93% (0–1 simplified scale) |

¶ 📈 Visualizing the Improvement

¶ Thermal Quality Comparison

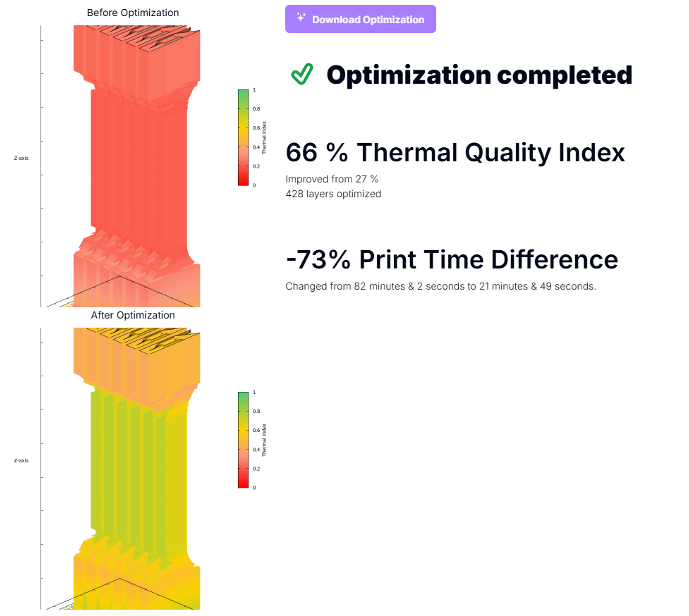

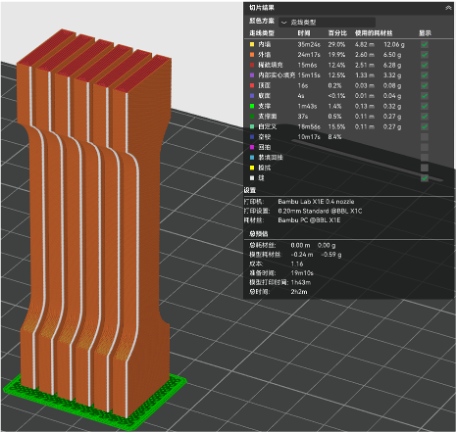

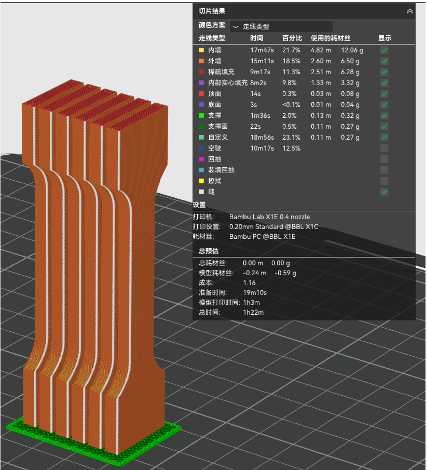

¶ With Fan (Red = Too Cold, Green = Better Bonding)

¶ Without Fan (Red = Too Cold, Green = Better Bonding)

¶ 🧪 Strength Results Per Sample

Each part was printed, tested, and the results logged:

| Sample | Bambu Default (MPa) | Dragon Optimized (MPa) |

|---|---|---|

| #1 | 33.7 | 44.9 |

| #2 | 29.77 | 54.9 |

| #3 | 27.79 | 52.2 |

| #4 | 30.42 | 55.4 |

| #5 | — | 44.0 |

🟠 Dragon parts were consistently stronger across all tests.

¶ 🕒 Print Time Comparison

Dragon not only improved strength — it also made prints faster:

- Before: 1 hour 43 minutes

- After: 1 hour 3 minutes

✅ 39% faster print time

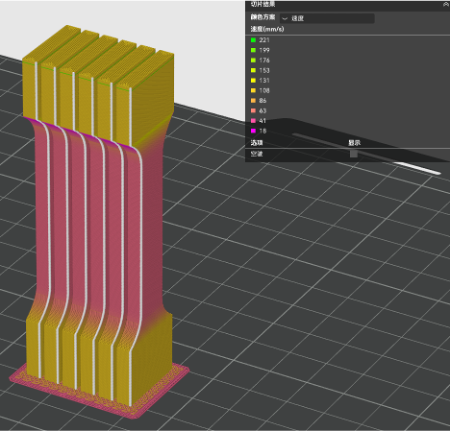

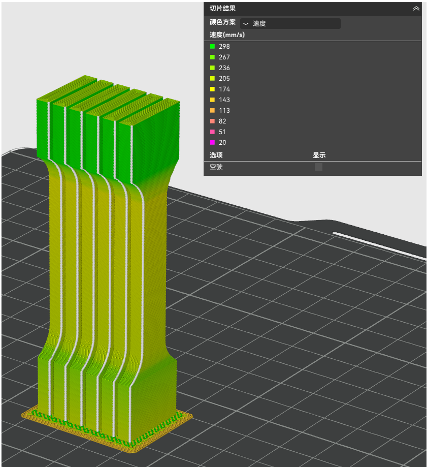

¶ ⏳ Before Optimization

Before (1h 43min):

¶ ⚡ After Optimization

After (1h 3min):

Dragon achieves this by printing faster where possible, and slowing down where needed for better bonding.

¶ 🧠 Final Thoughts

If you're printing parts that need strength (brackets, tools, functional components), don’t rely only on default slicer settings.

Using Helio Additive’s simulation and optimization tool, Dragon, you can:

- 🔥 Improve thermal quality layer-by-layer

- 💪 Boost part strength by 50–65%

- ⏱️ Reduce print times without losing quality

- 🧠 Make better decisions (e.g., cooling fan use) based on real data

Need help interpreting your thermal plots or print data?

Reach out to the Helio Additive team — we’re here to help.