¶ 🧠 Case Study: Faster PLA Prints with Dragon

With Helio Additive's Dragon simulation and optimization tool, we tested how far we could push PLA printing — faster speeds, better bonding, and no loss in surface quality. Here’s what we achieved:

- ⚡ 9% faster print time (6h 36m → 6h 0m)

- 🧪 Improved thermal quality index (-1 → -0.83)

- 🎯 Surface quality and detail preserved

¶ 🧰 How to Try This Yourself

- Slice your PLA model using a supported slicer

- Run the G-code through Dragon for simulation and optimization

- Review thermal results and tweak print settings if needed

- Print your prototype — faster, stronger, and just as precise

¶ 🧪 Faster PLA Prints with Dragon Optimization

PLA is one of the most widely used filaments in FDM printing — it’s inexpensive, easy to print, and reliably accurate. That’s why it’s the go-to for early-stage prototypes.

In this case study, we wanted to go one step further to investigate:

Can you print PLA even faster — while keeping part quality, strength, and dimensional accuracy?

¶ 🔍 What Did We Test?

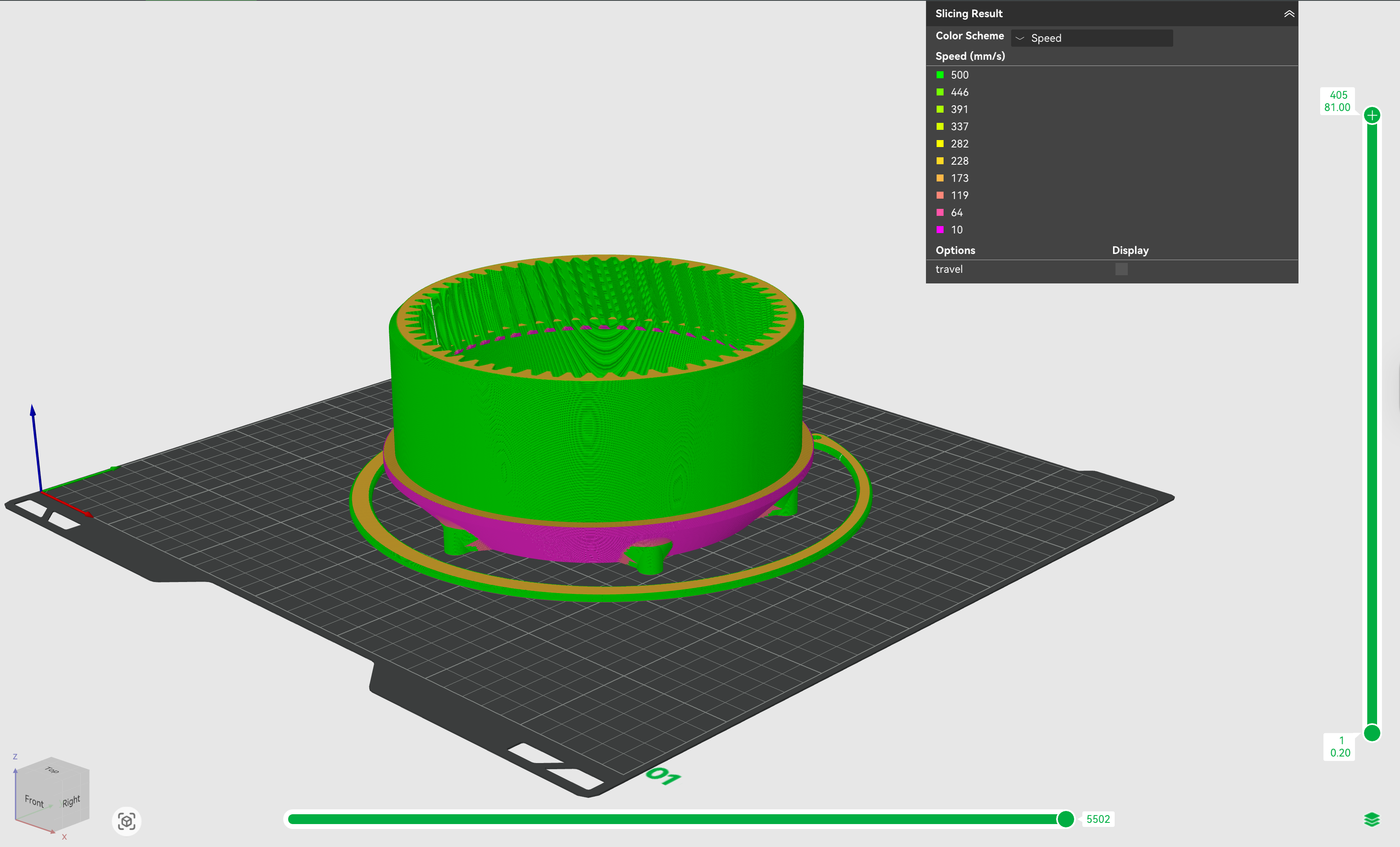

We printed a functional gearbox prototype, using two approaches:

- 🧵 Bambu Lab’s default PLA settings

- 🐉 Dragon-optimized G-code, with changes guided by thermal performance insights

We compared:

- 🔁 Print time (excluding prep and cooldown)

- 🎯 Surface quality and dimensional stability

- 🌡️ Thermal Quality Index (TQI)

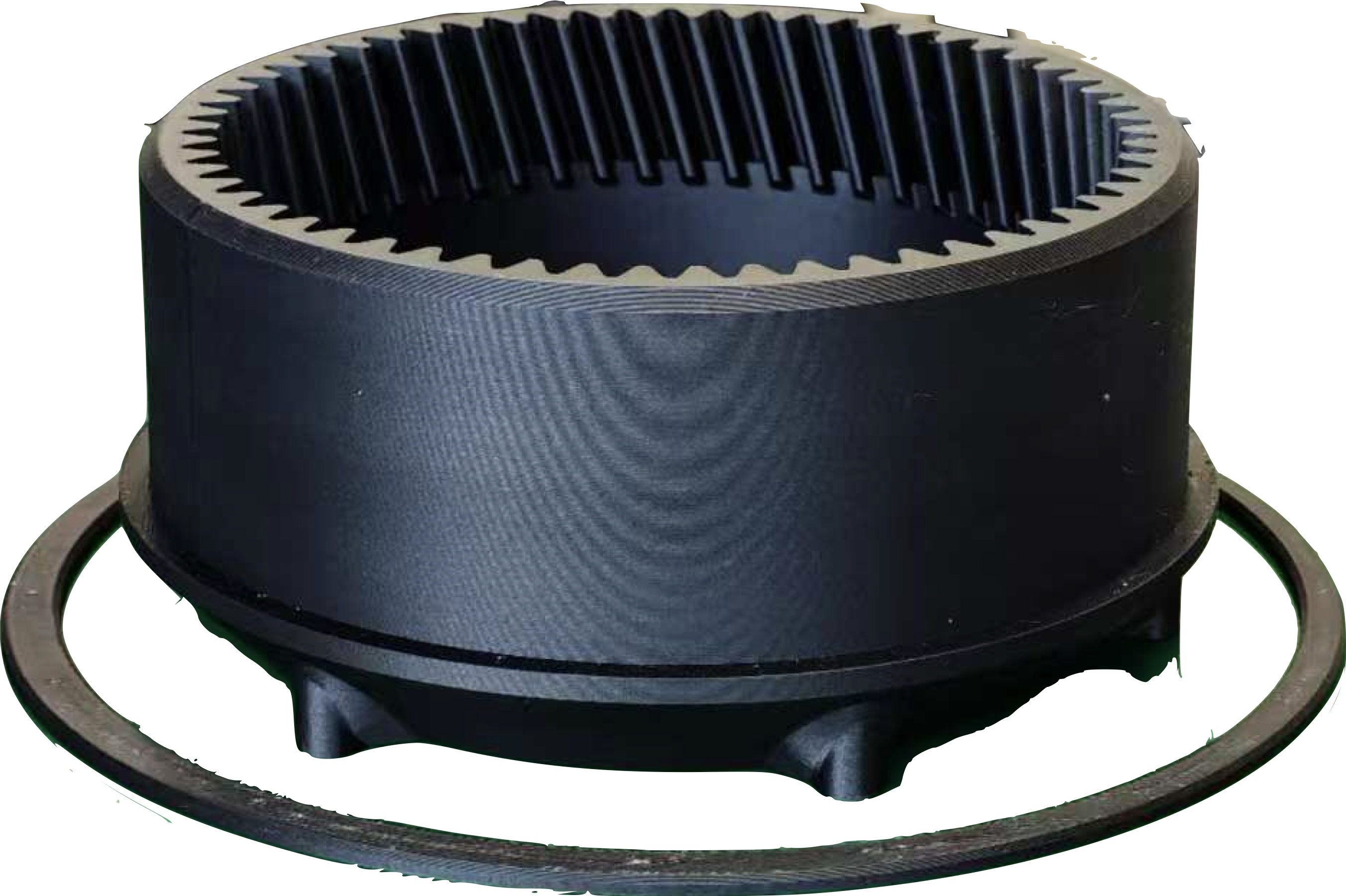

¶ ⚙️ Why This Model?

The gearbox model was chosen because it’s:

- 🔩 Structurally detailed (including gear teeth and fine features)

- 🧱 Large and complex (15% infill, long print time)

- 🧪 A real-world functional prototype — not just decorative

PLA is ideal for this use case: it’s low-cost, reliable, and dimensionally stable. But speeding it up without sacrificing quality is the real challenge — and that’s where Dragon came in.

We printed this part on the Bambu Lab H2D using Bambu Lab PLA Basic.

¶ 🧪 How We Tested It

To understand how Dragon could improve PLA print speed without affecting quality, we followed a controlled, step-by-step process:

- 🔧 Slicing:

We sliced the gearbox model in Bambu Studio using the default PLA profile — no changes to speed or cooling settings.

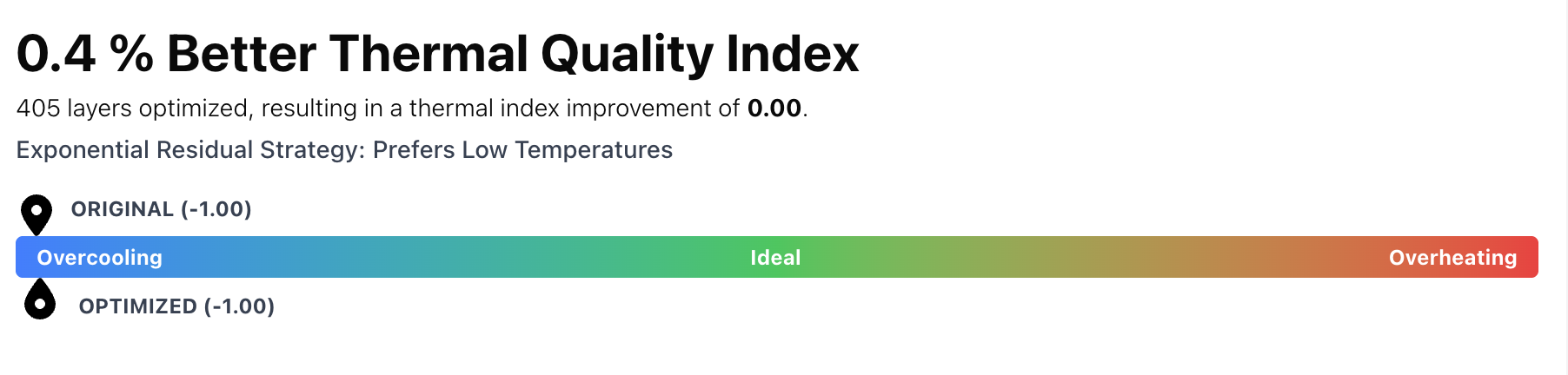

- 📉 Initial Optimisation:

We optimised unmodified G-code on Dragon to analyze thermal behavior.

Even at maximum print speed, the optimised results showed that layers were cooling too quickly — resulting in a low thermal quality index and no expected improvement in bonding strength.

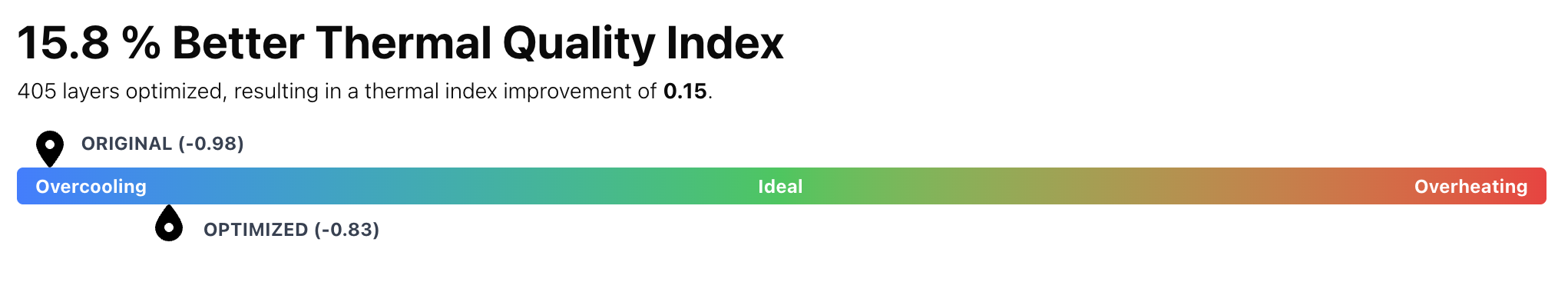

- 🌀 Fan Adjustment:

We manually adjusted the fan speed to 0%, then re-ran the thermal optimisation on Dragon.

This change made a clear improvement in the thermal quality index, from the original -1 to -0.83, meaning the layers were bonding better throughout the part.

- 🖨️ Printing & Measurement:

We printed both versions — the original and the optimized one, and manually timed the print duration.

Print time was measured from the first material deposition to the final extrusion, excluding setup actions like leveling or purging.

- 🎯 Surface Quality Comparison:

We visually inspected both prints and compared fine detail accuracy — specifically the gear teeth dimensions and sharpness — to confirm that the speed-up did not degrade resolution or finish quality.

⚠️ Note: Dragon did not modify the fan setting automatically — this change was made manually based on the optimization results.

Automatic fan speed adjustments are coming soon.

¶ 📚 Key Terms Explained

¶ 🔗 Bonding

Bonding is how well each printed layer sticks to the next one. Poor bonding leads to weak parts. Good bonding happens when the new layer melts into the previous one while it’s still warm.

¶ 🔥 Thermal Index

This is a value that helps us understand how close the print temperature is to ideal conditions for bonding.

The thermal index ranges from -1 to +1, where:

0= perfect bonding temperature< 0= too cold, poor bonding> 0= too hot, risk of deformation or sagging

💡 Note: More green= better layer bonding

¶ 🧪 Tensile Strength (MPa)

This is how strong the part is when pulled apart. Higher MPa = stronger print.

¶ 🕓 Print Time

Total time the printer takes to finish the job. Faster is usually better — as long as it doesn’t hurt quality.

¶ ✅ Results Summary

| Metric | Default Settings | Dragon Optimization |

|---|---|---|

| Print Time | 6h 36m | 6h 0m (-9%) |

| Surface Quality | Good | Good (maintained) |

| Thermal Quality Index (TQI) | -1 | -0.83 (17% better) |

Dragon achieved this improvement by intelligently pushing safe print speeds to their upper limits, while preserving the original (slower) speeds in geometry-sensitive areas like overhangs and corners, as shown in the next section.

This meant we gained print speed without sacrificing detail, as the optimizer maintained controlled conditions where quality mattered most.

🧠 Dragon’s optimization improved both speed and thermal performance — a dual win.

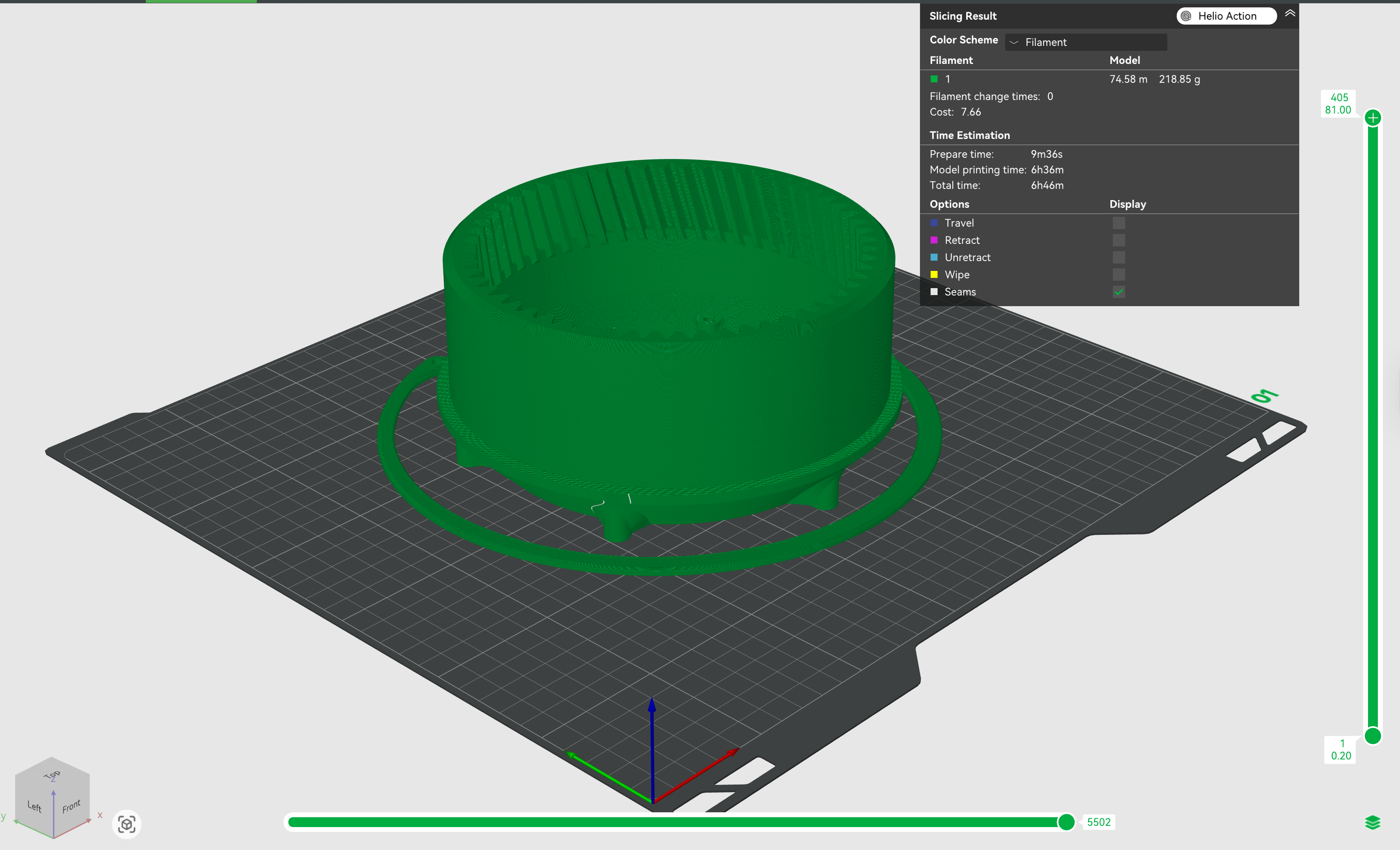

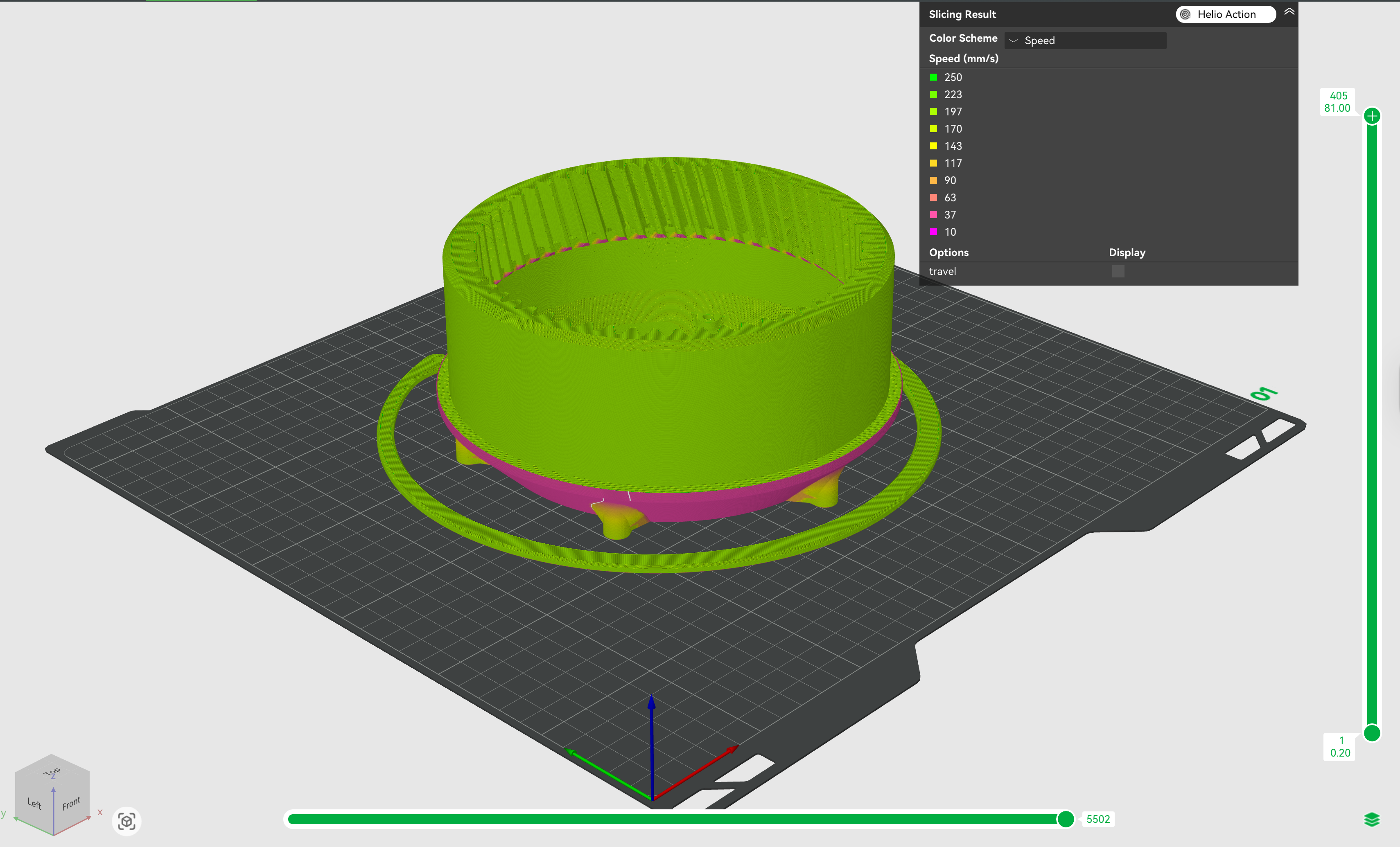

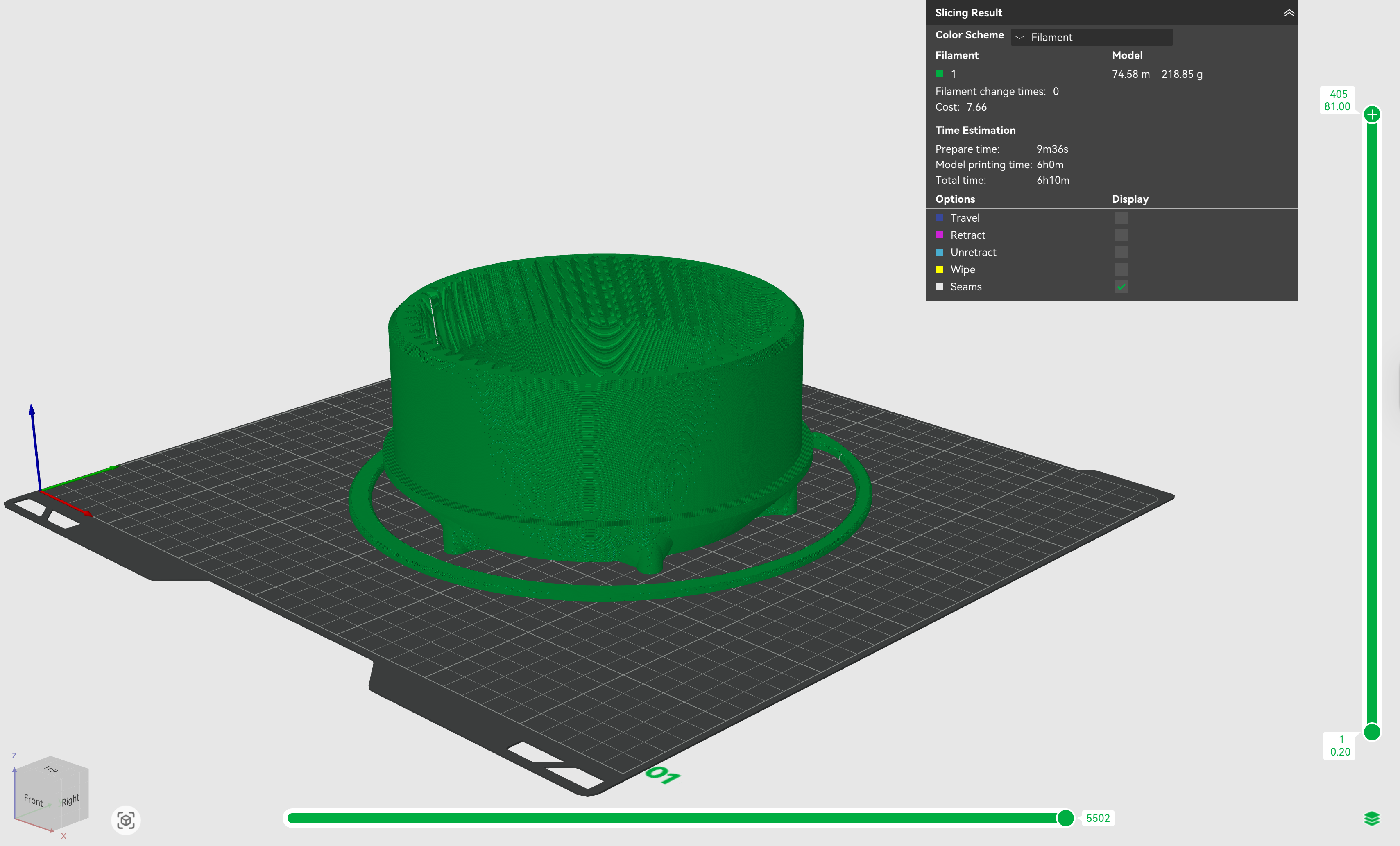

¶ 📊Visualising The Improvement

¶ Speeds and Print Time

¶ Before optimisation

¶ After optimisation

🧠 Note: Dragon carefully maintains slower speeds for sensitive features like overhangs, while safely increasing speed in less critical areas such as vertical walls.

This ensures faster prints without sacrificing detail or quality.

¶ Thermal Quality Index

¶ 🔄 Before Turning Off the Fan

In the first optimization run, the Thermal Quality Index (TQI) showed no improvement — the part remained too cold for reliable bonding.

This suggested that leaving the fan on would continue to limit print quality, even after optimizing G-code.

So, we turned the fan off and re-ran the optimization in Dragon.

¶ ✅ After Turning Off the Fan (optimization-informed decision)

After turning off the fan and re-running the optimization, the Thermal Quality Index (TQI) improved to -0.83, indicating stronger layer bonding and improved part strength.

¶

¶ 🧊 Why This Result Works — Especially with PLA

PLA is naturally more forgiving when printed a little cooler than ideal. Even with a lower thermal quality index, we still saw strong bonding and clean surface quality. Unlike materials like PC or ABS, PLA doesn’t usually warp or crack when slightly undercooled.

¶ 💡What does this show?

-

Faster doesn’t have to mean worse.

Dragon allowed us to reduce print time by over an hour without compromising detail or dimensional accuracy. -

Better thermal bonding = better performance.

The improved TQI suggests stronger interlayer adhesion, even at higher speeds. -

No trial-and-error tuning.

Dragon’s simulation gave clear insight into how speed affected bonding — so we adjusted with confidence.

¶ 🧠 Final Thoughts

If you’re printing prototypes with PLA, Dragon helps you:

- ⚡ Get faster prints without sacrificing surface detail

- 🧪 Improve bonding strength through thermal control

- 🔁 Make prototypes more repeatable and consistent

- 📉 Reduce print time — especially valuable for batch printing or iterative design

Faster prototyping = faster iterations = faster product development.

A ~10% time saving matters a lot when you’re printing 3–5 revisions a week.

–

Want help speeding up your PLA workflows without losing quality?

Book a Dragon demo →