¶ 🏗️ First-Time-Right Large Format (Pellet) Prints with Dragon

Using Helio Additive’s Dragon, we successfully optimized a challenging large-format pyramid print, achieving:

- ✅ First-time-right printing — no retries, no manual tuning

- 📉 30% reduction in warping and 83% reduction in deformation

- ⚡ 91% faster print time through intelligent layer speed optimization

Dragon automatically maintained ideal thermal conditions from base to tip

¶ 🧰 Want to Try Dragon for LFAM?

- Sign up on the dashboard and import your G-code to Dragon

- Simulate and optimize for thermal quality. Learn how to here

- Print with improved strength, speed, and repeatability

¶ 🧠 Smarter Printing for Large Scale (Pellet) Prints

For this case study, we partnered with Kuying Tech and Polymaker to optimize a large-format pyramid printed using the BRAMP300 robot-arm-based printer and Polymaker’s Polycore ASA3012 — a glass-filled thermoplastic.

The selected print model had previously shown signs of collapse and warping, likely caused by poor heating and cooling during printing.

We wanted to show that Dragon Dragon could:

- Fix a known print issue

- Help maintain part structural integrity and shape from base to tip

- Eliminate trial-and-error from the print process

¶ 🧪 Setup and Method

| Variable | Details |

|---|---|

| Printer | BRAM P300 (LFAM, robot-arm) |

| Material | Polycore ASA3012 (20% GF ASA) |

| Model | Large pyramid with tall Z-height |

| Software | Dragon + Coin Geoslicer |

Dragon takes in a G-code generated using Coin Robotics’ Geoslicer, pulling together geometry, toolpath, and material data in software for cloud-based optimisation.

Simulation environmental temperatures, were specified manually by the operator during the optimisation process. Accurately entering these values is important, as Dragon simulates and optimises the thermal behaviour of a print.

To simplify this step, the Dragon dashboard now only requires users to input the ambient air or chamber temperature. The software then estimates the remaining environmental conditions around the print.

Thermal cameras and rheological tests were used to build Dragon’s thermal model for PolyCore ASA3012 — a one-time process per material. Explore the full library of LFAM materials available in Dragon here.

To make sure the optimisation stays within your printer and material limits, Dragon takes into account your machine’s maximum speeds and the material’s flow rate range. These values are defined by the user.

The optimisation runs in the cloud and generates a new G-code, rewritten to deliver the best possible print results for the selected printer, material, and geometry. The user can then download this optimised G-code directly from the dashboard, ready for printing.

¶ 🔥 What Changed with Dragon?

¶ 📈 Key Results

| Metric | Before (default G-code) | After (Dragon-optimized) |

|---|---|---|

| Print Time | Baseline | ⏱️ 91% faster |

| Warping | High | 🔻 30% less |

| Deformation (Z-axis) | ~6mm | 🔻 Reduced to ~1mm |

| Success Rate | ❌ Repeated failures | ✅ First-time-right |

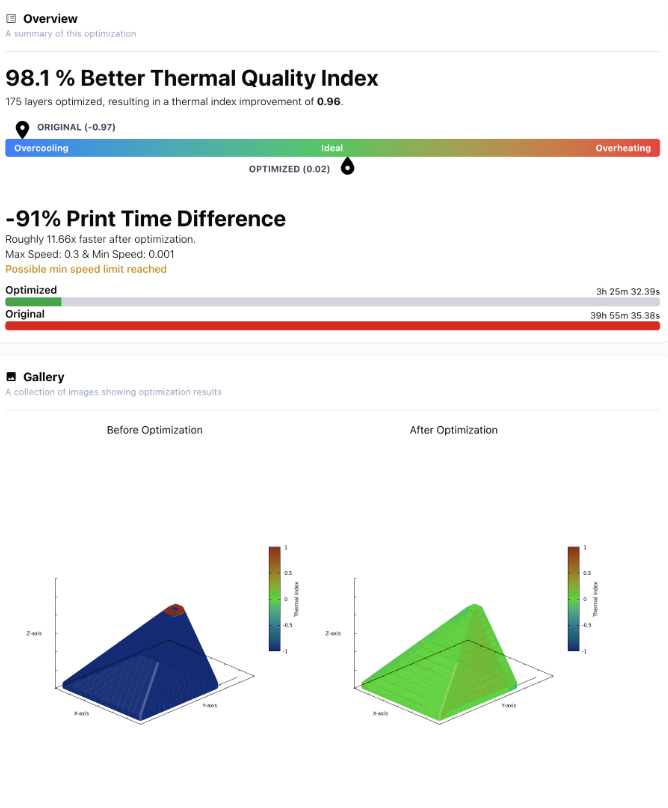

¶ 🔥 Thermal Behavior & Print Time

Dragon predicts thermal behaviour through a thermal quality index (-100→+100), where:

- -100 = Too cold → weak bonding

- 0 = Ideal bonding temperature → successful, strong print

- +100 = Too hot → part collapse

For the default G-code:

- The thermal index was consitently poor for all layers layers

- The upper region was too hot, leading to collapse before the print could finish

- Printed in ~40 hours

After Dragon-optimised the G-code:

- The index remained stable and closer to ideal

- Result: better bonding, less stress, gemoetry integrity maintained

- Print time reduced to ~3.5 hours

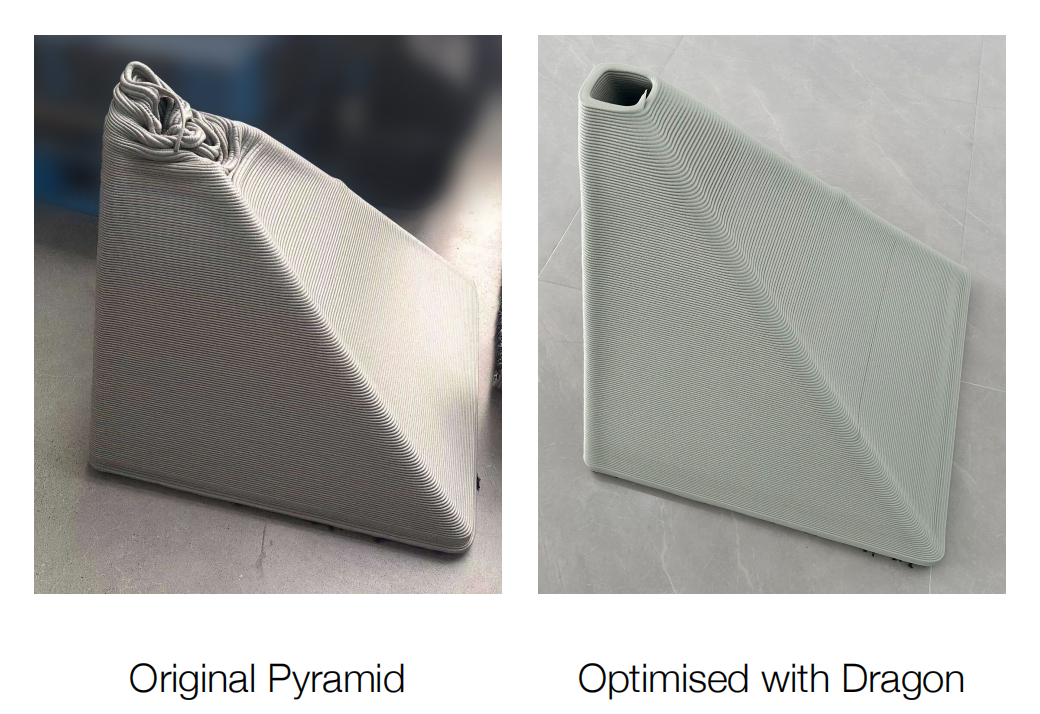

¶ 📦 Print results

Before optimisation:

- The original print showed unstable thermal index values: too cold for the majority of the first layers, too hot higher up.

- This caused inconsistent bonding, deformation, and a high failure rate.

After optimisaton:

- Dragon adjusted print speed layer-by-layer to keep the thermal index stable

- The pyramid printed with no collapses or overhang deformation

- Dragon kept thermal conditions within the optimal window throughout

🔍 A fixed speed was not suitable to print this model. Dragon identified this and adjusted the print speed to keep the object within the ideal thermal window, automatically.

¶ 🧠 Why It Works

Dragon’s physics-based engine models:

- How each voxel in the part heats and cools

- How speed, toolpath, and airflow affect temperature during the print process

- How thermal history translates into mechanical strength

This enables:

- Smart speed control at each layer

- Reduced residual stress

- Stronger, more repeatable parts without guesswork

¶ ✅ Final Thoughts

This case shows how Dragon transforms high-risk LFAM prints into repeatable, production-ready parts.

With no hardware changes, we achieved:

- 💪 Stronger parts

- ⚡ Faster prints

- ✅ Zero tuning failures

🛠️ Dragon isn’t just for predicting problems — it’s for printing right the first time.

Want to optimize your large-format or high-risk print?

Book a demo with Helio Additive →