¶ Filament Material Library: Faster, Stronger, Less Warping

Helio currently supports 28 commonly used FDM materials, which can be simulated and optimized to improve your print results — making them faster, stronger, and less prone to warping. We are constantly adding to this list. For full compatibility, refer to supported materials here.

We ran internal validation tests to confirm that Dragon consistently delivers measurable improvements in both part quality and material performance.

While results will vary depending on your part’s geometry, size, and print settings, most materials supported in Bambu Studio and Orca Slicer showed clear gains when optimized with Dragon — including faster print times, stronger bonding, and improved dimensional stability.

¶ ⚙️ What is Dragon?

Dragon is a product by Helio Additive that simulates and optimizes your G-code before printing.

It helps you:

- Adjust speed layer-by-layer to improve bonding and reduce thermal stress

- Analyze how temperature affects print quality

- Find the fastest way to print without sacrificing strength

🧠 Dragon doesn’t just optimize blindly — it uses a physics-based simulation to predict how your part heats and cools in real time.

¶ 🧪 Test Methodology

We evaluated print speed, warping, and mechanical strength using a structured approach that combined simulation, manual measurement, and physical testing of printed parts.

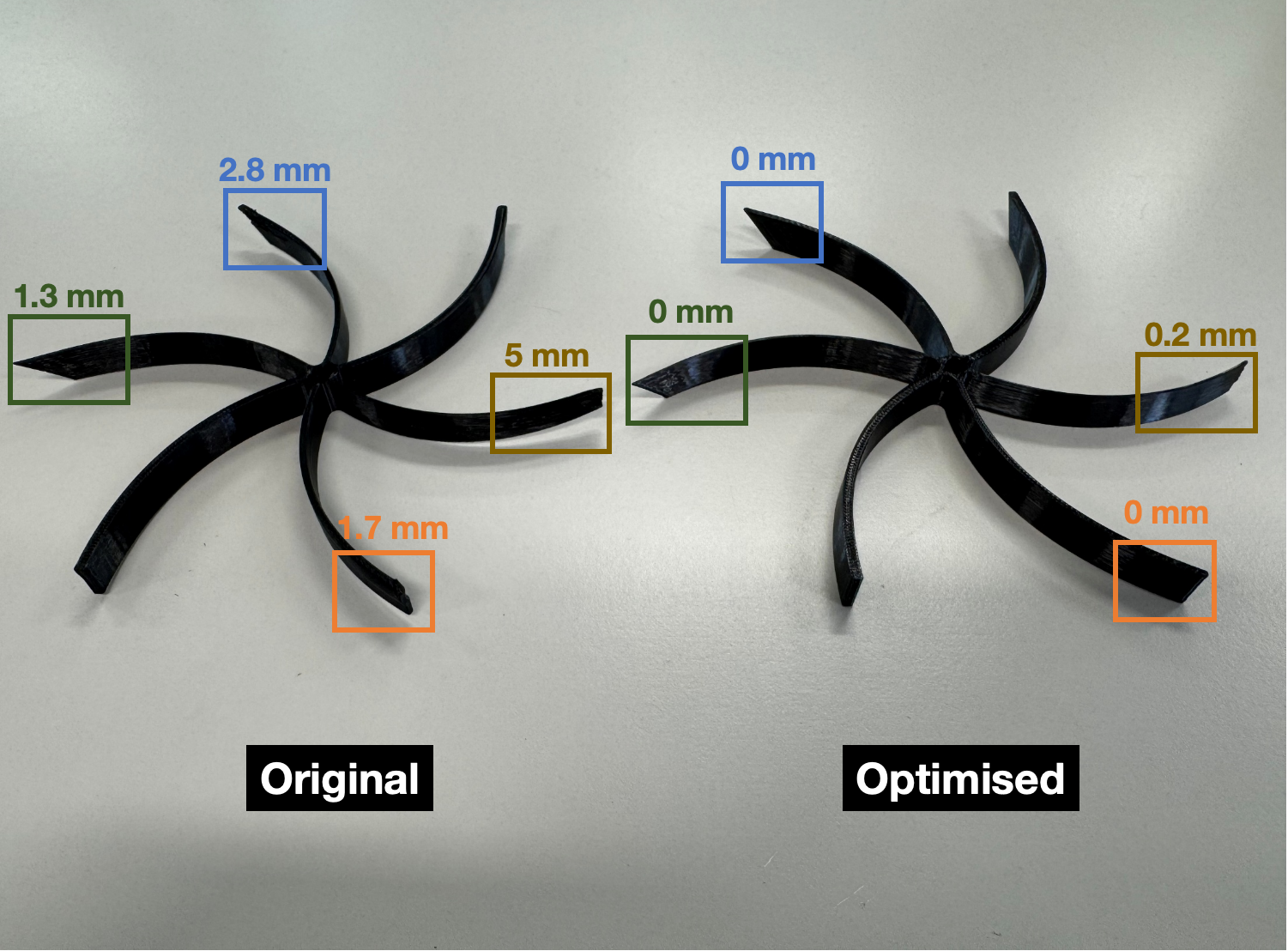

¶ 🔄 Warping & Print Time

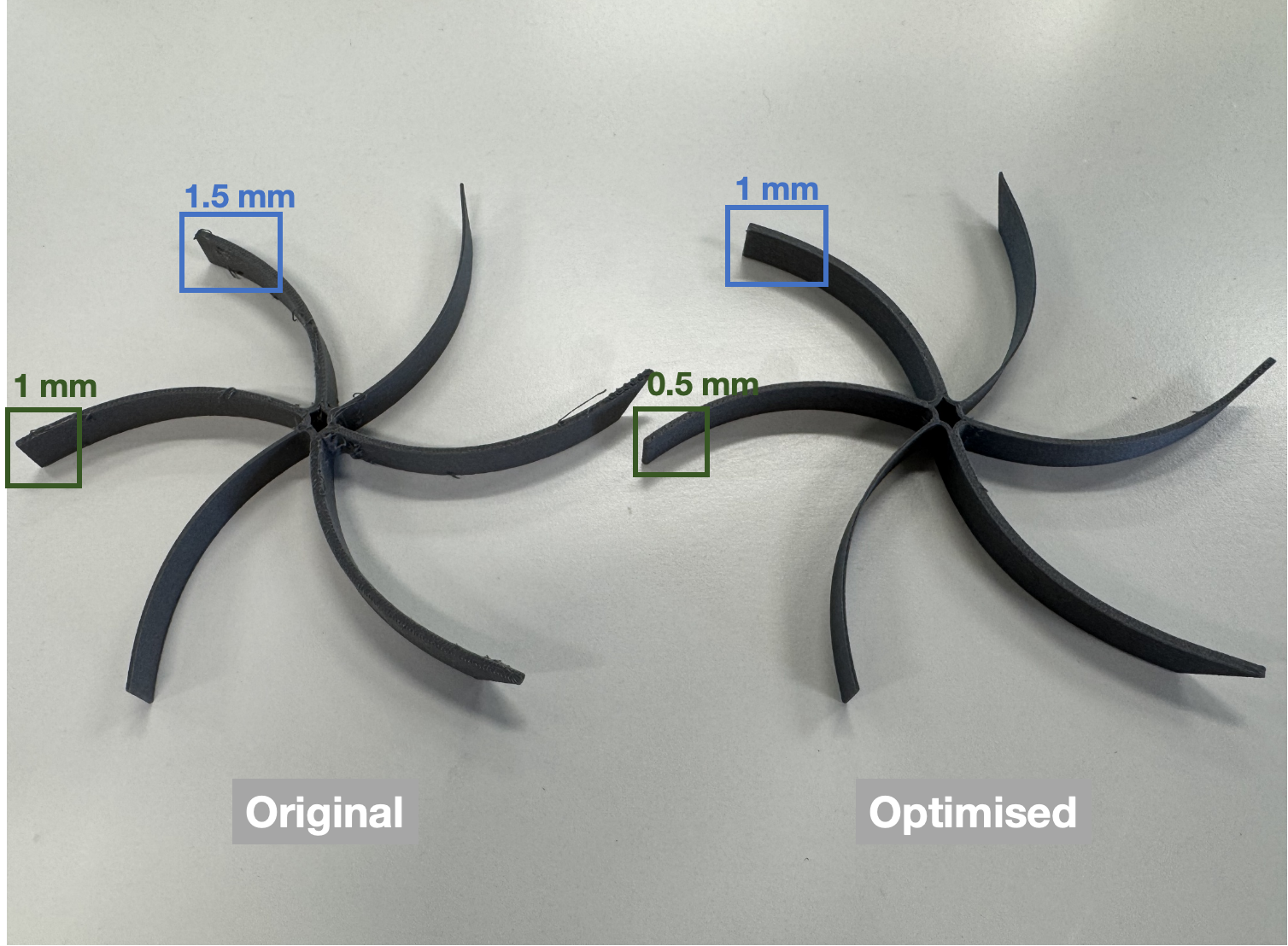

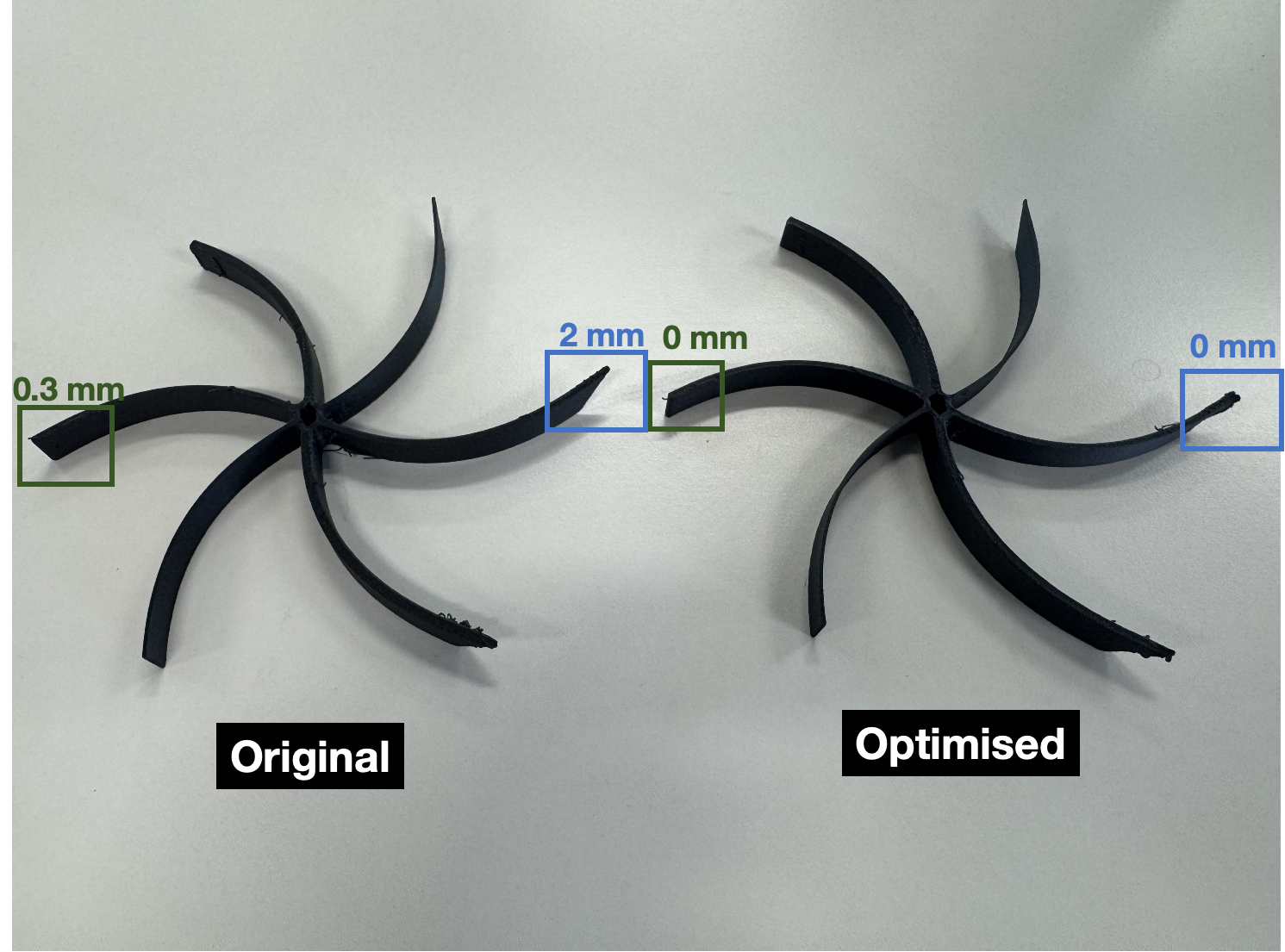

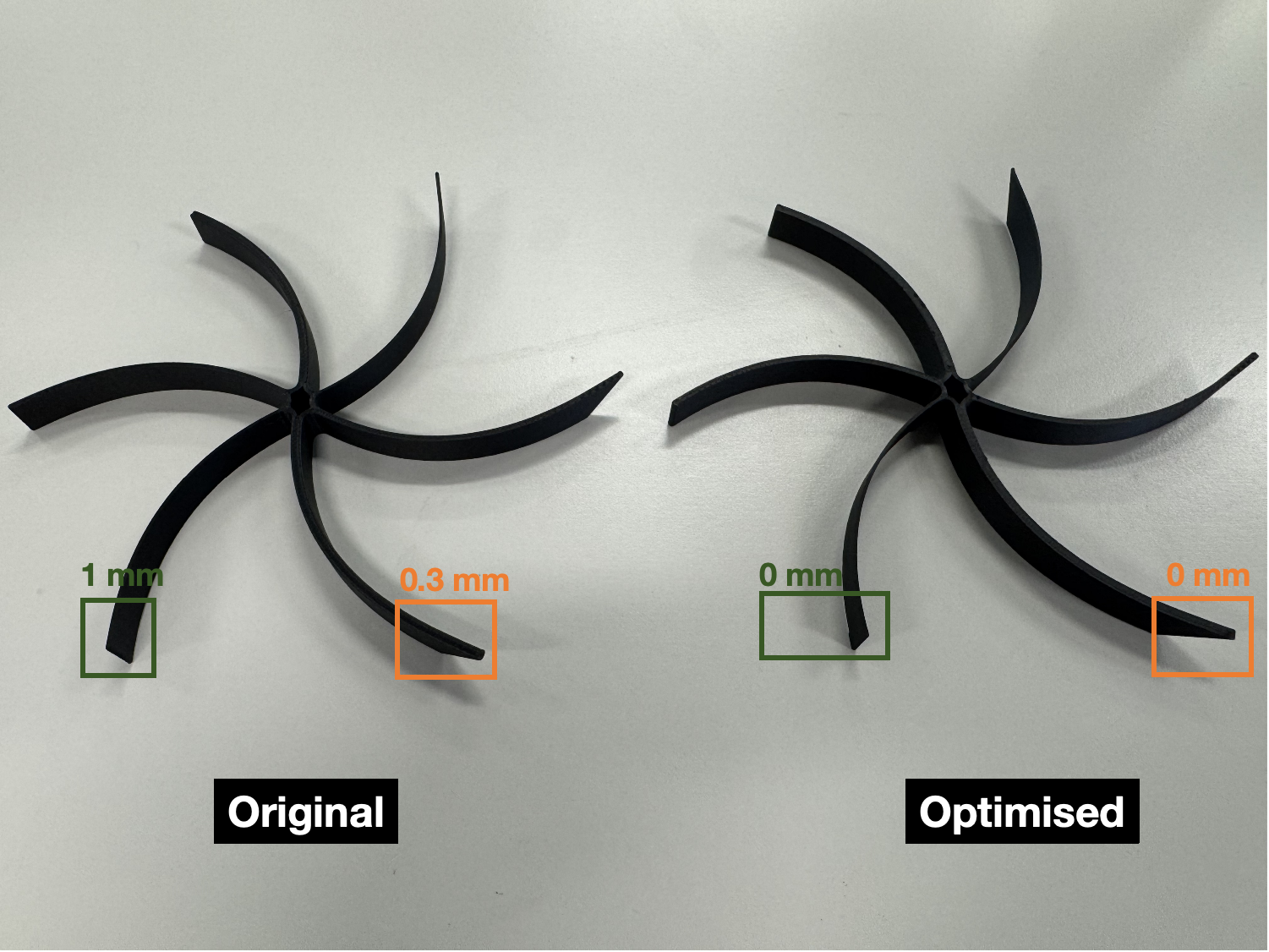

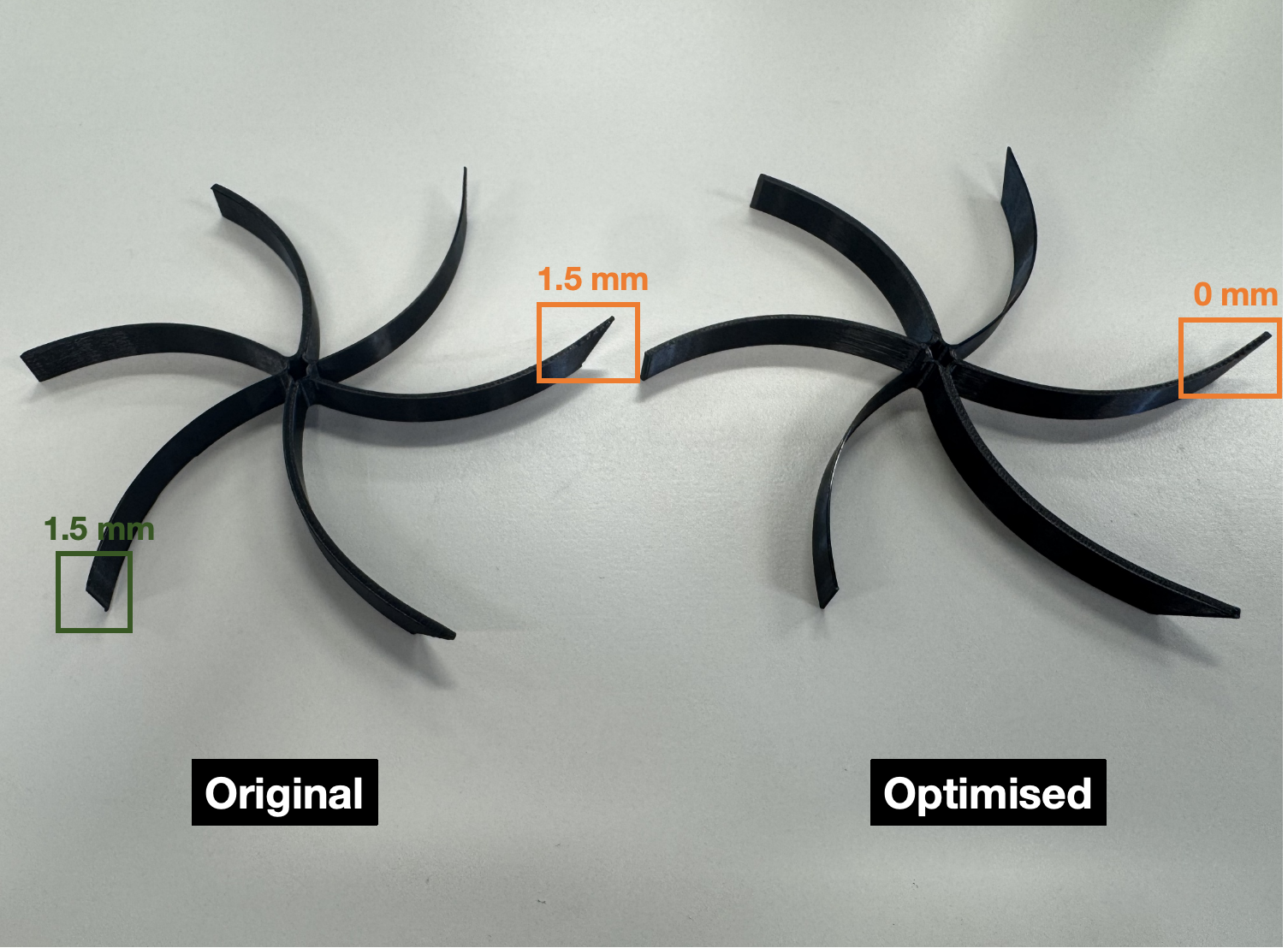

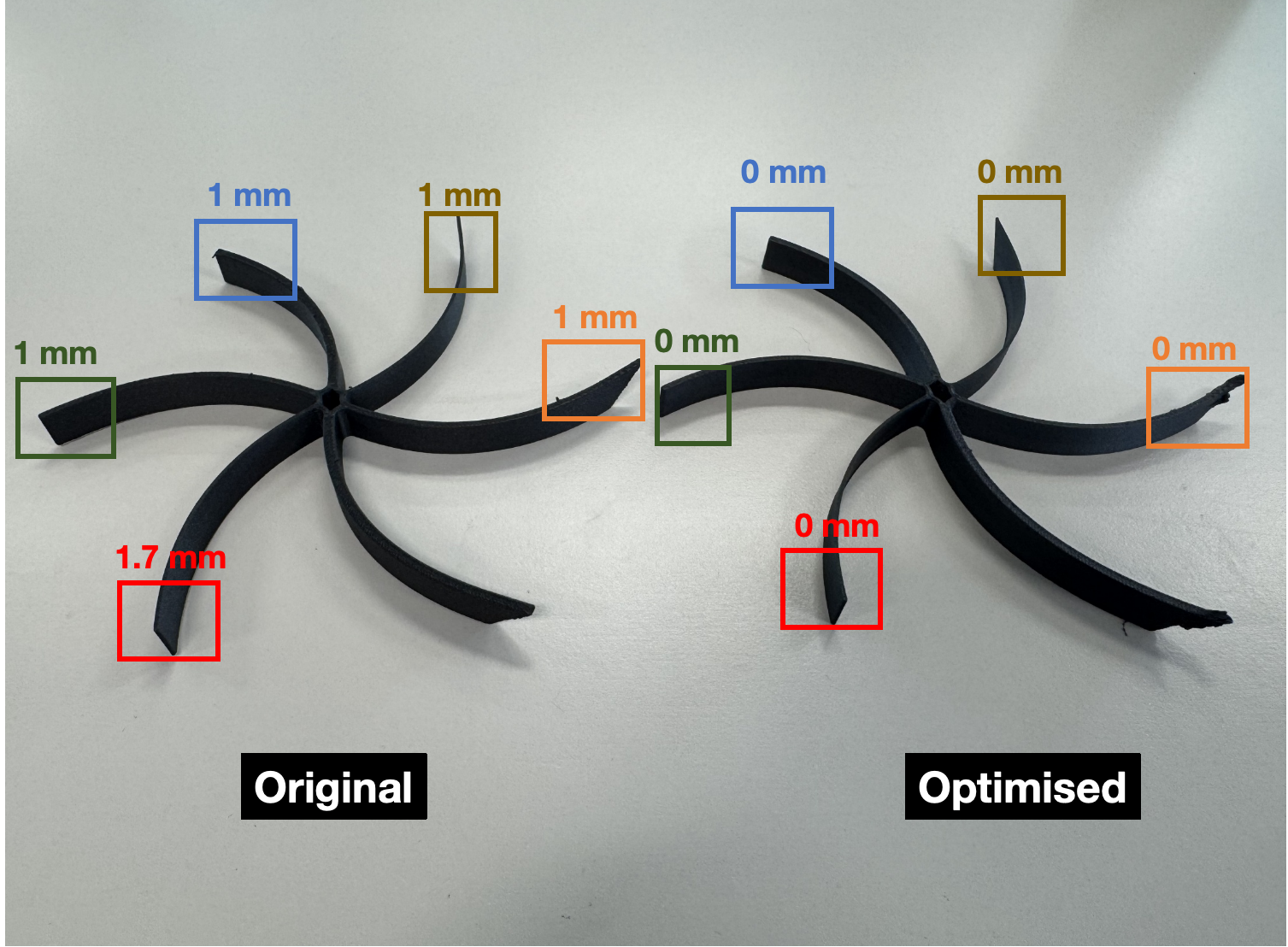

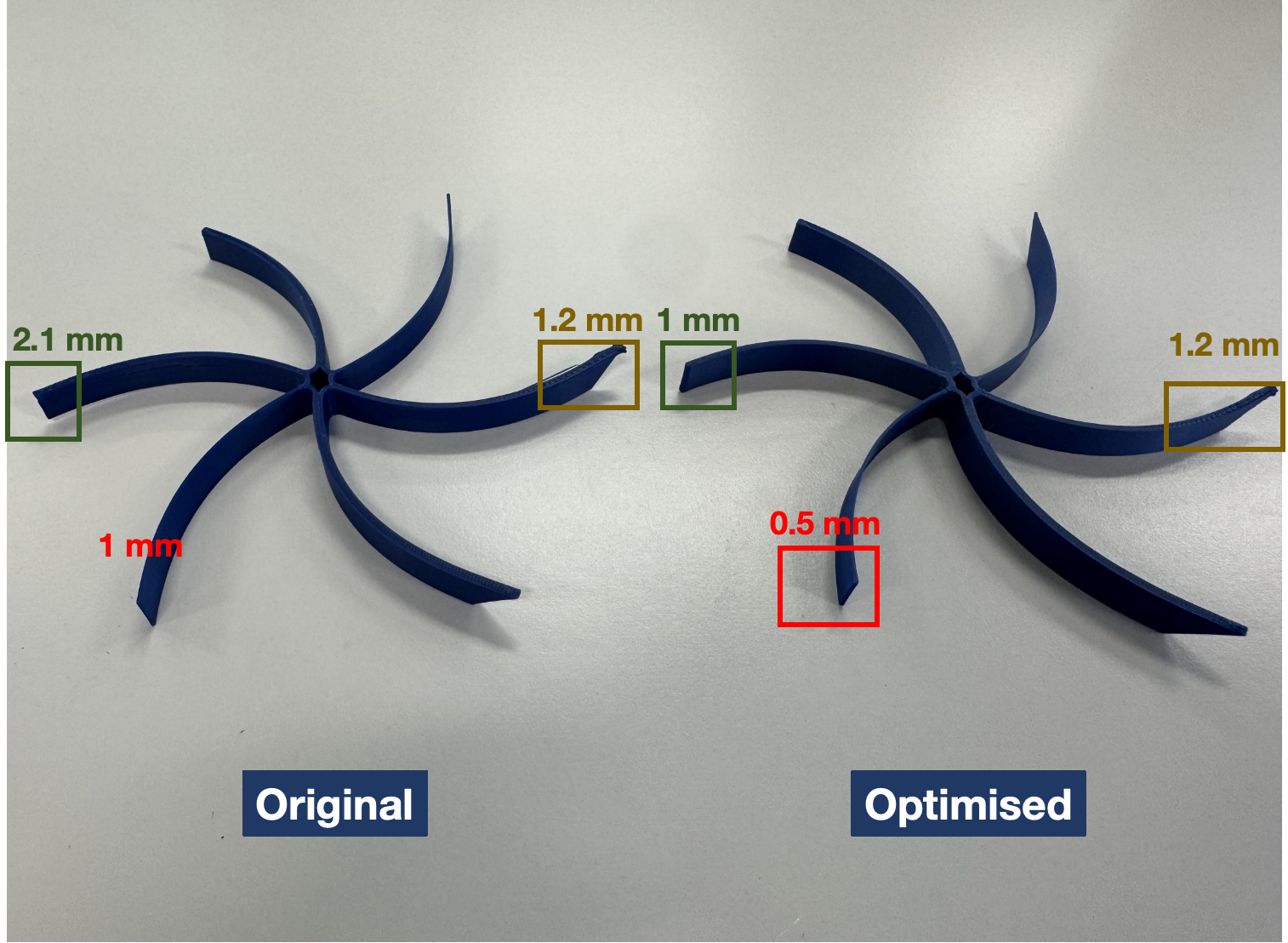

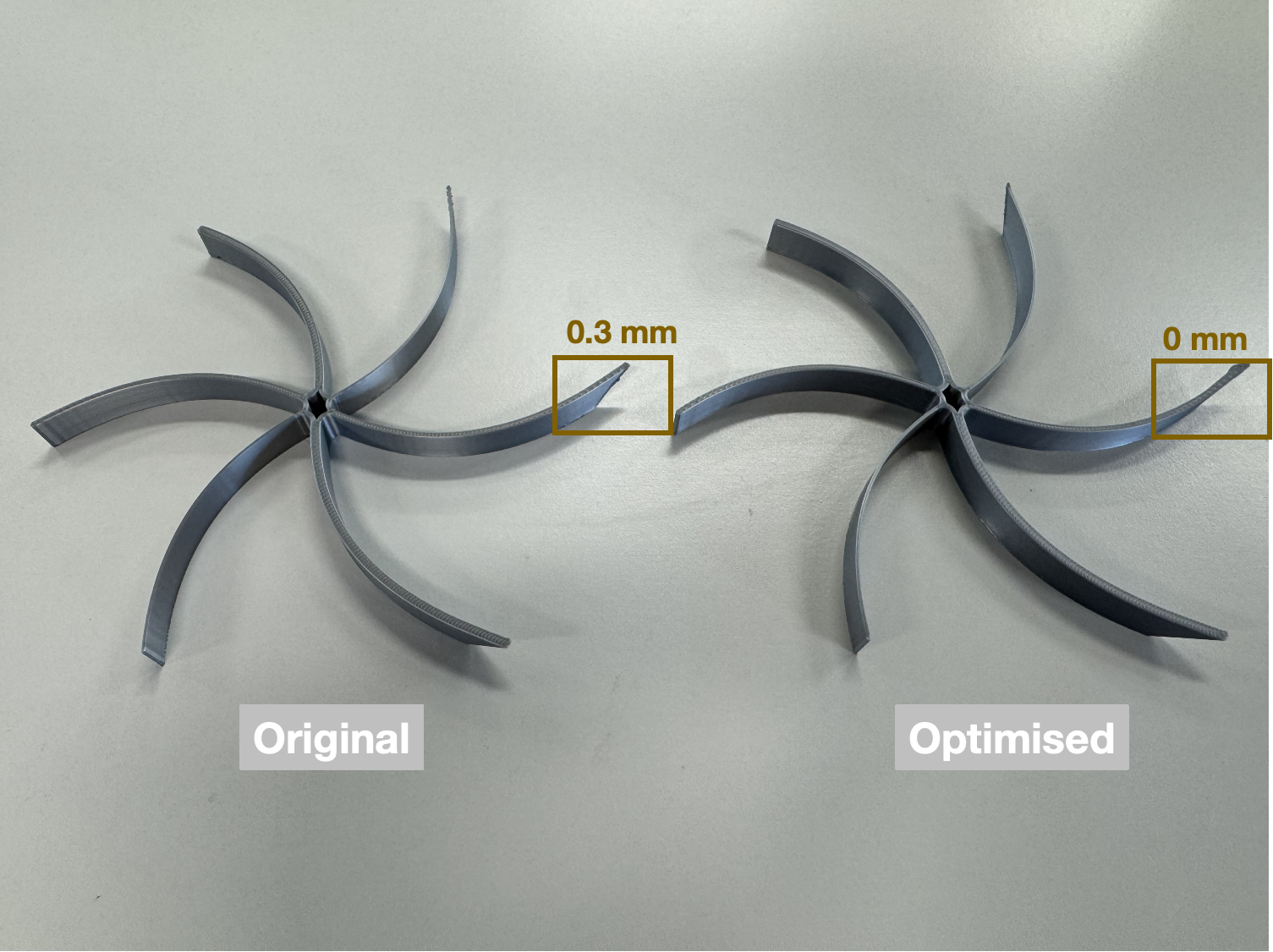

To assess dimensional stability and print time improvements, we used a standardized warp test object from Brainprint licensed under CC BY-NC-SA.

This test part is specifically designed to evaluate warping behavior across both 90° vertical walls and 45° overhangs, for three different thicknesses.

The model features three sets of two arms with equal thickness:

- One arm ends in a 90° vertical wall (no overhang)

- The other ends in a 45° overhang, which challenges successful printing without warping or drooping

This setup allows us to directly observe and measure warping across different geometric conditions.

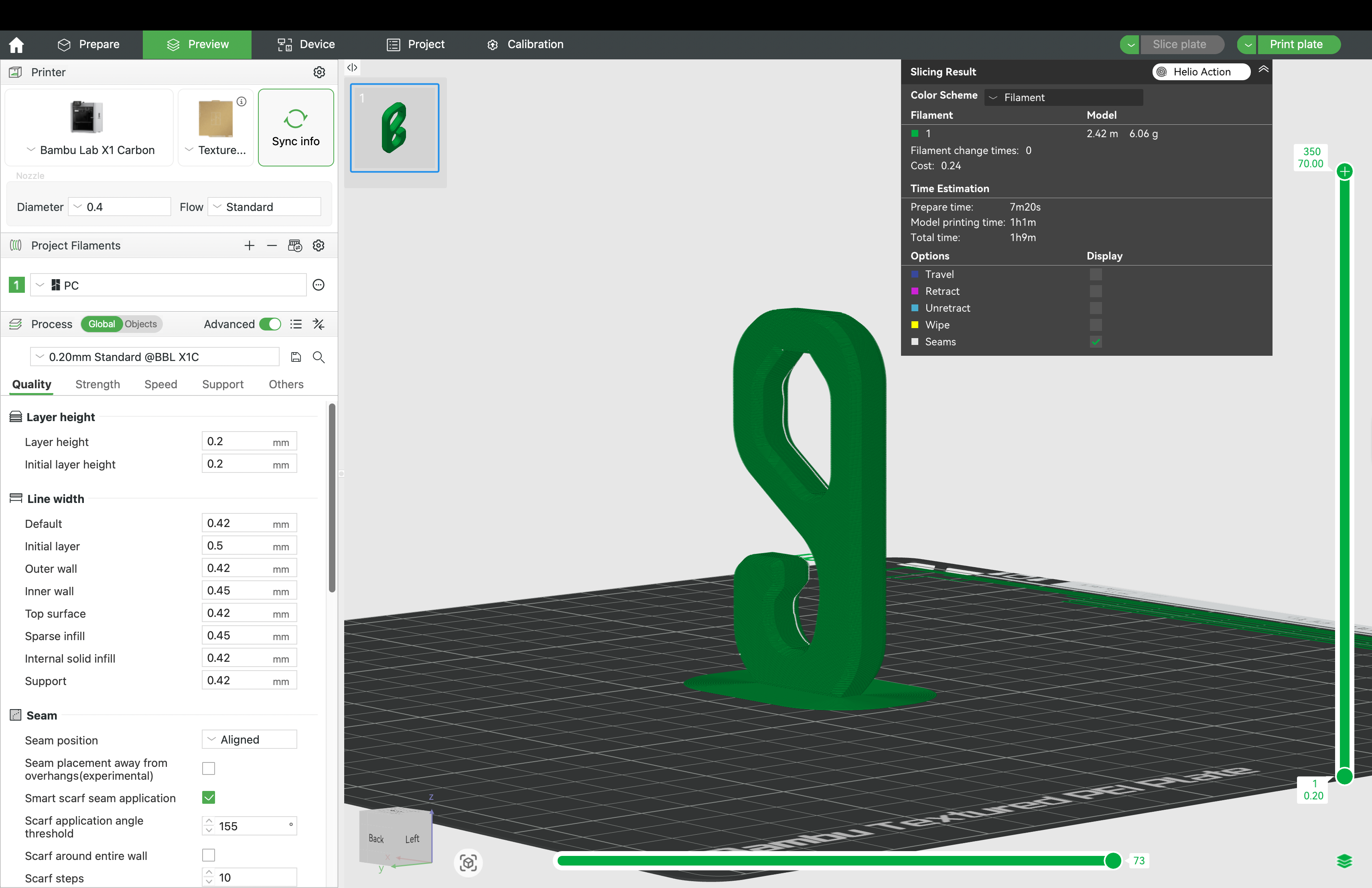

Each sample was printed using:

- The default Bambu slicer settings

- Dragon-optimized G-code (after thermal simulation)

Warping was measured as follows:

- Visual inspection and measurement of vertical lift in millimeters at six corresponding locations on each part.

- We calculated the percentage difference in warping for each point (original vs. optimized).

- The average of these six values gave a single warping improvement score per sample.

Print time was manually recorded for both the original and optimized samples, measured from first material deposition to final layer completion. We excluded prep steps like leveling and purging.

The improvement was calculated by comparing the total print time between the original and optimized prints.

¶ 💪 Bonding & Strength

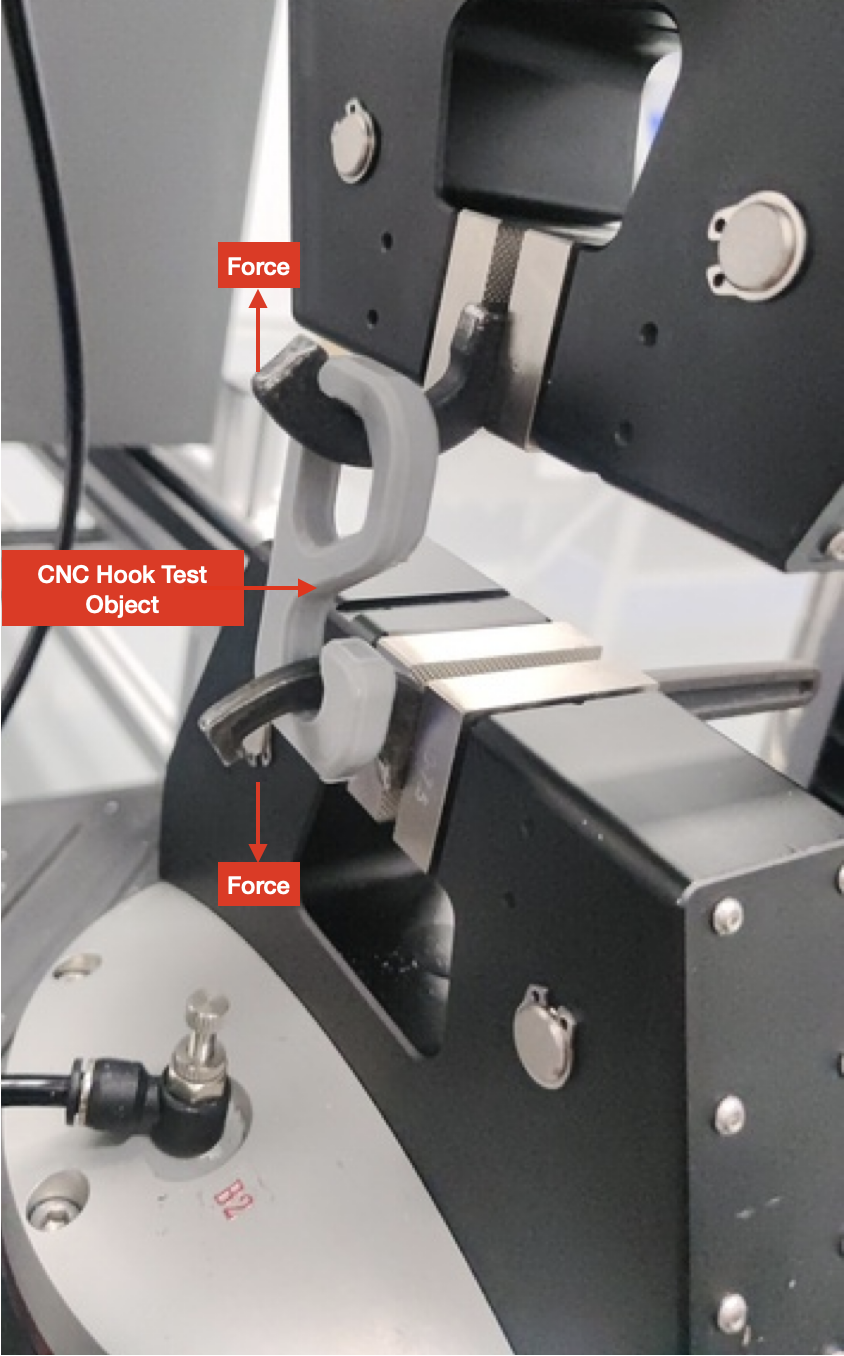

We used a tensile hook test designed by CNC Kitchen to evaluate layer adhesion and mechanical strength under practical loading conditions.

Baseline parts were printed using standardized slicer settings, with 3 wall loops and 30% infill to provide additional strength.

All samples were printed vertically, standing on their narrow end, with the bonding surfaces perpendicular to the Z-axis — allowing us to directly assess improvements in Z-direction strength resulting from Dragon’s enhanced layer bonding.

We then optimized the G-codes for those baseline parts using Dragon to improve layer bonding and reduce thermal stress.

Both the original and optimized samples were then tested for their load-bearing capacity using a Universal Testing Machine (UTM), where the samples were pulled to failure and the maximum load at failure was recorded in Newtons (N).

The parts were hooked on both ends of the UTM, pulled apart until failure, and the maximum load was recorded.

Since the tensile hook is not a standardized test object with a well-defined cross-sectional area like a dogbone test object, the strength is reported as the maximum load (Newtons) the part could bear before failure, rather than stress (force per unit area).

This method showed real, practical improvements in part strength — thanks to Dragon’s ability to improve how well each layer bonds to the next.

⚙️ Note: The warp tests were performed on a Bambu Lab X1C using a 0.4 mm nozzle.

¶ 📈How We Categorized Improvements

Warping, print speed and tensile strenght improvements were categorized as follows:

| Improvement (%) | Category |

|---|---|

| ≤ 10% | Low or n/a |

| 10–20% | Medium |

| > 20% | High |

¶ 🧪 Our Material Test Results

📌 Note: “n/a” means the part had little or no visible warping to begin with.

💡 Click the image to view it full size.

¶ 🔵 Polymaker and Fiberon Materials

| Material | Print Time Improvement | Warping Improvement | Strength Improvement |

|---|---|---|---|

| High | n/a |

Low | |

| High | Low | ||

| High | Low | ||

| High | Low | ||

| High | Low | ||

| High | Low | ||

| High | High | ||

| High | n/a |

Low | |

| Low | n/a |

High | |

| Low | n/a |

High | |

| Low | n/a |

Low |

¶ 🟢 Bambu Lab Materials

| Material | Print Time Improvement | Warping Improvement | Strength Improvement |

|---|---|---|---|

| Medium | n/a |

Medium | |

| Low | n/a |

Low | |

| Medium | Medium | ||

| Medium | n/a |

Low | |

| Medium | n/a |

Medium | |

| High | n/a |

Low | |

| High | High | ||

| High | n/a |

Low |

¶ 📁 Test Files

We’ve provided both the original .3mf files and the Dragon-optimized .gcode files, so you can review the changes in your slicer or replicate the tests on your own printer.

- Download original warp test .3mf files

- Download optimsied warp test gcode files

- Download original tensile test .3mf files

- Download optimised tensile test .gcode files

ℹ️ Tip: For best results, open these files using the latest version of Bambu Studio.